PRODUCT CATALOG

17 products have been posted by this company

Lark Engineering Company

India

India

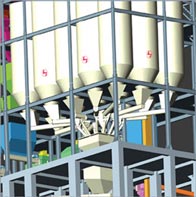

Lark successfully designed and commissioned its first fully automatic controlled plant at M/s Unnat Feeds, Panipat, Haryana, India in February 2008. The plant capacity is 6 ton/hr on pellet and 8-10 MT/ hr on mash. The Plant reflects our designing capability in terms of unique features..

Our 200 MT/hr plant supplied to M/s Sri Krishan Kripa Feeds, Panipat, India, has following features: Plant designed to give 10 ton/day Pellet of 2.5 mm size and 15 MT/hr mash. Hammer mill working on 100 H.P with our patented gap adjustment technology to give..

Our Plant at Hygiene Feeds, Panipat, India has Following Features: Plant output is 6 MT/hr Pellet of 2.5 mm size and 8-10 MT/hr mash. Hammer mill working on 60 H.P, Grinding 6 MT/hr. 1 ton/batch double ribbon screw mixer with double door..

Our 2-3 MT/hr Pellet Feed Plant has Following Features: Plant output is 3 MT/hr Pellet of 3 mm size and 4-6 MT/hr mash. Hammer mill working on 40 H.P, Grinding 3 MT/hr 1 MT/batch Double Ribbon Screw Mixer working on 15 H.P..

Our bagging machine is designed for automatic filling of material in open mouth bags. The machine is net filling type and in this, material to be bagged is weighed in a weigh hopper and is emptied into bag. The machine is fitted below an overhead storage bin with flexible connection and..

For the production of quality feed, it is of utmost importance that all the ingredients and micro ingredients (vitamins, additives and trace elements) are measured in weight with high precision so that the desired percentage of each can be ensured in final feed.As the no. of ingredients and volume..

The

pellets & crumbs are usually screened to separate fines & over

size particles before final packing. For removing fines only, we require

single deck screener. For removing both the over size & fines, we..

Crumbling is the process of breaking pellets in small pieces by passing these through rolls rotating at different speeds having grooves on surface. After the hot pellets are cooled to the ambient teprature, the pellets may require breaking into small pieces to feed day-old chicks and grower..

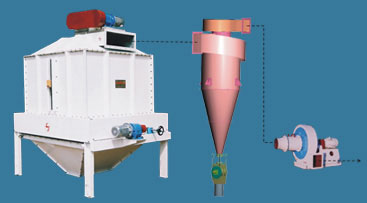

Evenly distribution of pellets to maintain even bed height is essential to avoid uneven cooling.Butterfly Valve is provided on I. D. Fan to control the optimum volume of air required for effective cooling. Level Sensor can be adjusted up or down to control the height of bed of..

Pellet Chamber or front door is made of corrosion/wear resistant, single wall, heavy duty, SS-304 grade stainless steel for longer life. Hinges on Pellet Chamber may be fitted for left or right opening as per requirement ..

This machine is based on Weight less Zone or Fluidized Zone mixing technology with many modifications at Lark Engg. Co. (India). In this machine, two shafts are positioned in a double drum housing on which series of blades (generally 14 on each shaft) are fixed. The two shafts rotate at a..

Double Ribbon Screw Mixer with side outlet is suitable for direct bagging from mixer and where mixer is normally installed at ground floor level.ConstructionThese mixers consists of U-shaped horizontal trough in which a heavy duty shaft with two ribbons in helix shape at different pitch circle..

Double Ribbom Screw Mixer with full width discharge bottom provide very fast discharge of mixer and are suitable for plants having mixer fitted at some height (i.e., on struchure)and have surge bin below it. Due to fast discharging, segregation at discharge is greatly avoided.ConstructionThese..

These mixers produce a very homogeneous mix of different ingredients

used in feed industry. In this machine, mixing is performed by four

curved blades clamped on main shaft which when revolve give continuous

turbulent movement to the ingredients. Arrangement is given for direct

addition..

Even if a hammer mill is properly designed and well matched to its required job, it may not perform well if it is not fed properly.A typical hammer mill feeder is expected to meet following requirements. The feeder must provide a "UNIFORM CURTAIN" of materials to hammer mill grinding..

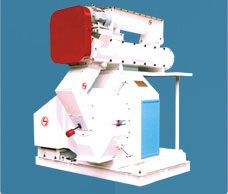

This machine is used for reducing the particle size of different

ingredients in feed . It consists of a rotor on which swinging hammers

are mounted in different patterns which when rotate at high speed,

strike with incoming feed ingredients and break these. Required fineness

of final..

As its name implies, Full screen hammer mill have 80 % screening area

as compare to 50 % in half screen hammer mill. This machine is an

answer to many fine or coarse grinding problems that we usually face.

Our Full screen hammer mill has so many other features also that..