Found 19 Matching Products

principle of work

drum-type drier is tilted slightly and the cylindrical rotating

body,the wet material enter into the upper,at the same time,the dry

materials are collected on the other side of the lower part.Hot air from

the feed end or discharge end access to the..

Introduction to Fish Feed Pellet DryerWhen the pellets are discharged from the fish feed machine, the pellets temperature can be 90℃ and moisture about 18%. The temperature must be reduced quickly to ambient and moisture to 8%-12% for storage. We can supply two types of feed pellets dryer,..

ellyz

SWDB series granulated feed stabilizer is a post-curing equipment aiming

to improve the grain quality; with long stabilizing time, it can

further improve the curing degree of granulate feed and mixing affect

and quality, improve obviously the stability of granulated feed in

water, delay the..

This machine adopts low-speed rotarying,curved plate hammering,dispersing raw material,making the high-temperature air flow current mixed with raw material ,so that we can achieve the drying goal.it mainly applied to drying process of all kinds of ash raw material.it can be widely used in the fuel..

1. Belt driving and high strengthens screening hull are supported by elastic nylon sheet.

2. Little flour dust, low noise, little vibration, smooth operation and long service life.

3. Smooth running and good classified effect, easily maintenance.

After cooling pelletize temperature under +5℃~+8℃ in room;Be provided with special efficacy for self-motion egest material,abstain pollute between drink;Adhibit capot debar feed cashing force debar feed;Adopt special egest material casing glide blandly,running placidly;Apply to..

Working Principle of Gas Fish Feed Pellet Dyer

After fish feed pellets are feeded evenly into the dryer, they will be spread on the dryer bottom by the rotatory spreader. The hot air of steam radiator will penetrate material layers and take the moisture away. Then dry pellets are pushed to the..

ellyz

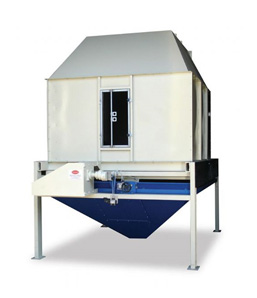

Counterflow process is the refined technology of exposing processed product to an upward moving stream of ambient airflow. HET counter-flow dryer concept is based on the first-in, first-out principle, with a full separation of batches/layers. It is well suited for..

Specifications• 3 grated, reverse air current cooler system• Adjustable, electro pneumatic controlled pellet discharging speed• Moving Discharging grate commanded with brake reducer• Transparent control glass• 2 pieces of level control sensor• Collecting hopper• Air lock• Aspiration gate with air..

1: Principle of workdrum-type drier is tilted slightly and the cylindrical rotating body,the wet material enter into the upper,at the same time,the dry materials are collected on the other side of the lower part.Hot air from the feed end or discharge end access to the material and discharge from..