Found 19 Matching Products

The drier is consisted hot-wind stove(ready by customer),screw feeder,buffer,blower,the pipes and cyclone.the work process is that the air flow is formed through the negative pressure of blower,the materials enter into the pipe through the screw feeder,so that the hot wind and materials mix..

The drier is consisted hot-wind stove(ready by customer),screw feeder,buffer,blower,the pipes and cyclone.the work process is that the air flow is formed through the negative pressure of blower,the materials enter into the pipe through the screw feeder,so that the hot wind and materials mix..

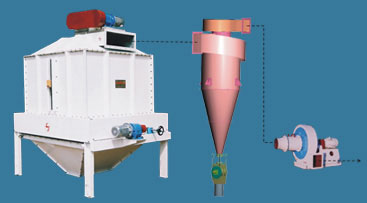

1. By adopting counter flow cooling theory,pellet can be cooled ully and equally.2. Slide valve slug clearance hole is used,thus makes the operation stable and makes the material discharge be easy and smooth.3. The temperation of cooled pellet is not higher than room temperature

1. Concentrate the functions of refining ( aging later) and cooling the pellet in it, its construction is compact and the automation degree is high;2. The internal layer of the conditioner is made by stainless steel, steam tracing the interlayer, nollie blowdown, the refining time is up to..

Counter-flow process is the refined technology of exposing product to an upward moving stream of ambient airflowThe cool air meets the hot pellet feed creating convection, effectively removing moisture from the pellets and reducing their temperatureStainless steel modern hexagonal structure..

Evenly distribution of pellets to maintain even bed height is essential to avoid uneven cooling.Butterfly Valve is provided on I. D. Fan to control the optimum volume of air required for effective cooling. Level Sensor can be adjusted up or down to control the height of bed of..

The counterflow pellet cooler is applied for efficient cooling of hot and moist pelleted products with good flowing capabilities. Typical applications are for cooling of feed pellets and wood pellets. It can reduce the temperature of pellets from 80~90℃to about 3~5℃ above ambient..

yvonnezhao

1. With counter flow cooling principle, the pellets can be cooled thoroughly and evenly.

2. Maintenance simply and installation conveniently.

3. The temperature of pellets is no more than 3-5 centigrade higher than the environmental temperature.

4. Slide valve or swing rod discharging..

1. Always take cooling effect on the pellets when the air from cold to hot, make full use of the air, as the result that need less air, low energy expenditure and no condensation;2. The charge-in uniformly distributed, omnibearing blowdown in the bottom, evenly cool down the pellet;3. Equipped with..