PRODUCT CATALOG

39 products have been posted by this company

HET Feed Machinery

China

China

Complete turnkey feed production line for the production of feed pellets.

Complete turnkey feed production line for the production of aquafeed and fish feeds.

Proportioning System: Auto computer controlled batching of ingredients. Ingredients are proportioned to the proportioning bins then automatically dosed, weighed and a batch prepared for the mixer.

Complete grinding plant for the grinding and powdering of different materials.

Complete turnkey feed production line for the production of poultry feed.

Complete turnkey feed production line for the production of shrimp feed.

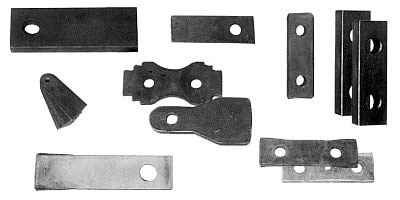

We manufacture replacement sets of hammers for use in hammer mills

We manufacture conditioners for the fitting on existing pellet mills.

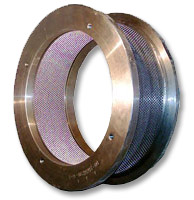

We manufacture a range of pellet rolls and are able to meet OEM orders for custom rolls.

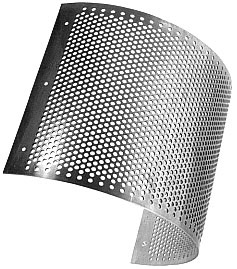

We manufacture a range of pellet dies and are able to meet OEM orders for custom dies.

Rotary Allot Valve used to proportion ingredients into different proportioning bins before pelleting.

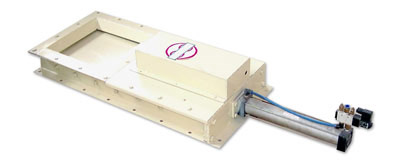

Pneumatically controlled gateFeaturing rigid profile slide frame, pneumatic cylinder, micro switches, electromagnetic conversion valveIncl. solenoid valve for air control

Air lock feeding device for feeding, so as to avoid the air crossing at the feeding inlet

consisting of:• elevator foot reinforced with sectional steel, with belt pulley, control flaps, and discharge slides• inlet• belt with buckets• one shaft• elevator head reinforced with hood, belt pulley, return stop, and motor bracket• drive with geared motor, power: 3 kWSuited to handling a wide..

Timing Screw Feeder, used in the conveying of materials in the feed mill.

for continuous and adjustable feedingconsisting of:• worm case for thread(s)

• worm shafts with special draw-in

thread

• geared motor with frequency

converter

Rough and preliminary cleaning is employed when receiving grain, maize,

raw rice and similar products. Used in feed factories, flour factories,

grain warehouses and other trades recieving these materials. Used to

screen and eliminate large impurities from the raw materials, protecting

the..

Our HET TCXT tubular magnet is perfect for the removal of ferrous impurities from the raw materials. Widely used in feed factories, grain and oil processing factories, wineries, solvent factories, etc

Pulse Bag Dust Collector :

- has high dust removal efficiency over a wide range of particle types and sizes

- lower operating and maintenance costs

- effective compliance with regulatory standards

Pulse Bag Dust Collector :- has high dust removal efficiency over a wide range of particle types and sizes- lower operating and maintenance costs- effective compliance with regulatory standards

HET Screeners are responsible for separating dry materials according to particle size, providing accurate screening and seperation.

Responsible for separating dry material according to particle size, providing accurate screening and separationManufactured from stainless steel in order to keep a high level of sanitation necessary in the food processing industryFailsafe, rigid design with easy control and operationHigh..

The HET Pellet Crumbler is essential equipment for the preparation of crumbled pellet feed. Used for breaking the pellets into crumbs suitable for shrimp, young chicks, etc.Exact adjustment of the roll gap by hand-wheel allows easy operation and adjustment of the..

Counterflow process is the refined technology of exposing processed product to an upward moving stream of ambient airflow. HET counter-flow dryer concept is based on the first-in, first-out principle, with a full separation of batches/layers. It is well suited for..

Counter-flow process is the refined technology of exposing product to an upward moving stream of ambient airflowThe cool air meets the hot pellet feed creating convection, effectively removing moisture from the pellets and reducing their temperatureStainless steel modern hexagonal structure..

Providing retention time at high temperatures after pelletising or extrusion, the post-conditioner allows conditioning of the pellets before drying or cooling starts. Correct conditioning of a feed compound is necessary in order to achieve good pellet quality.Specifications:SKSQ100Capacity (t/h):..

Equipped with conditioner the injection of steam and water in either the preconditioner and/or the extruder, is adjustable.Specifications:Power (kW): 55/75/90Capacity (t/h): Soybean - 1-2.5, Powder - 0.6-1.2

Dry extruders are designed to run without moisture or prior conditioning of the raw materials.Widely used for soybean, corn, low moisture highly expanded starch products, slaughtered animal waste, etc for use in the food and feed industries.Specifications:Power (kW): 55Capacity (t/h): Soybean -..

Pellet mills responsible for the production of quality fish, and shrimp feeds.Pelleting press consisting of screw feeder, through screws with full face paddle, shafts made of stainless steel, driving belt, driving wheel, coupling assembly and overload protection system. multi-stage..

Pellet mills responsible for the production of quality fish, poultry, and livestock feeds.Our pellet mills offer performance, durability, efficiency, strength, flexibility and safety as standard.Pelleting press consisting of screw feeder, through screws with full face paddle, shafts made of..

Used in the mixing of feed additives, pre-mixes, feed, chemicals and pharmaceuticalsSpecifications:SSHJ0.2Power (kW): 3Capacity (t/batch): 0.1SSHJ0.5Power (kW): 5.5Capacity (t/batch): 0.25SSHJ1Power (kW): 11Capacity (t/batch): 0.5SSHJ2Power (kW): 18.5Capacity (t/batch): 1

Used in the mixing of various light and heavy products, with improved liquid atomizing and mixing effectiveness while preventing agglomerationDesign features big "U" shaped, heavy steel plate, horizontal mixing chamber Double ribbon screw type rotor provides higher mixing uniformityTop spraying..

Horizontal mixer for the mixing of feed additives before manual loading material into feed ingredients hopper, and into the main mixer.Specifications: - Mix capacity: 100kg/batch, (0.2m3) ..

Used for grinding and micro grinding such raw ingredients as wheat, maize, dehydrated fish, shrimp shells, defattened soybean, monosodium glutamate, sugar, medicines, dying material intermediates, ore,etc.Specifications:SWFL80Power (kW): 45, 55, 75Capacity (t/h): 0.8-1.5SWFL102Power (kW):..

The 9FQ50 hammer mill utilizes a high speed hammer to effectively pulverize material .This small scale model has been a popular choice for small to medium scale feed factories along with farmers Specifications:Power: 15 kW , Capacity: 0.8-1.2 t/h

Used for manufacturing high-grade feed for livestock and poultry feed, aquafeed and used in grain distillations, the production of citrus acid and food processing plants.Rugged all stainless steel plate casing The grinding chamber is of teardrop shape, effectively eliminating circular flow in the..

Used for manufacturing high-grade feed for livestock and poultry feed, aquafeed and used in grain distillations, the production of citrus acid and food processing plants.Rugged all stainless steel plate casing The grinding chamber is of teardrop shape, effectively eliminating circular flow in the..