PRODUCT CATALOG

42 products have been posted by this company

Zhangqiu Yulong Machine Co., Ltd

China

China

Packing machines are widely used in pellet making whole lines.This make the transportation of the pellets much more convenient. Normally, they are at the end of the making process to pack the pellets into bags. The bags can be 5KG, 10KG, 20KG and so on, this depends.This kind of packing..

Permanent-magnet Tanks are widely used

in the pellet making whole lines, for example, wood pellets making line,

animal feed pellets making line, and fertilizer pellet making line.

They are normally used in front of the whole line to prevent the irons

and other impurity of the raw material..

The ring dies are made of two types material: carbon steel or stainless steel. They have a good hardness and a long lifetime. The diameter of the hole can be 1.5-12mm.

The belt conveyors are also one important part in the whole pellet making lines. They are used for transporting the raw materials and the finished products--pellets.The belt conveyor also has transducer to adjust the rate of the transporting. What is more, if it is needed, magnetic rollers will be..

1. The stream line shaped discharge hole can make no material being left in the material and avoid cross contamination.2. The screen structure is simple and conbenient.screen layer can be fixed accordingly.3. It can be used not only for the grading and secondary circulation comminuting of pellet..

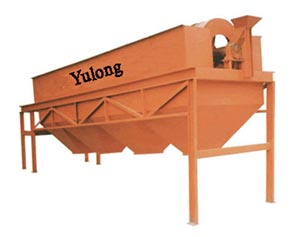

Feature of these series are very simple. The machines work placidly,reliable on screening with huge high quantity of output,easy to repair.They can stage screening raw material according to different screen holes,mainly use for complex mixing fertilizer

The external form is beautiful, the conformation is compact. It is a comprehensive pre-cleaning machine with feature of adjustable cylindrical screen tilt angle and function of separating samll, large and mediem sized impurities simultaneously.

The stream line shaped is designed for discharging hole. It can make materials neither left nor contamination.The pressed screener structure is simple and convenient. Screener can be rotary quickly. Screen layer can be fixed accordingly.It can be used not only for the grading and secondary..

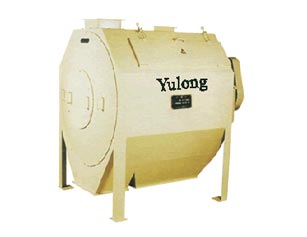

Degree of homogeneity cv < 5-7%,mixing eifficiency is high.it uses manual operating,electric driving and steam driven wide opening discharge,residual in the machine is little,it can be widely used in feedstuff plants,cultivation farms,chemical plants,food products factories,flourmills,etc.

Operation speed low, mixing efficiency high, and moving is gentle. Various liquids can be added.Mixing time is short (40-60 seconds/group), and the coefficient of variation is low (CV<5%).Full-opened structure makes no material left, and the output speed is fast.It is suitable for premix..

Operation speed low, mixing efficiency high, and moving is gentle. Various liquids can be added.Mixing time is short (40-60 seconds/group), and the coefficient of variation is low (CV<5%).Full-opened structure makes no material left, and the output speed is fast.It is suitable for premix..

Operation speed low, mixing efficiency high, and moving is gentle. Various liquids can be added.Mixing time is short (40-60 seconds/group), and the coefficient of variation is low (CV<5%).Full-opened structure makes no material left, and the output speed is fast.It is suitable for premix..

The drier is consisted hot-wind stove(ready by customer),screw feeder,buffer,blower,the pipes and cyclone.the work process is that the air flow is formed through the negative pressure of blower,the materials enter into the pipe through the screw feeder,so that the hot wind and materials mix..

1. By adopting counter flow cooling theory,pellet can be cooled ully and equally.2. Slide valve slug clearance hole is used,thus makes the operation stable and makes the material discharge be easy and smooth.3. The temperation of cooled pellet is not higher than room temperature

This machine adopts low-speed rotarying,curved plate hammering,dispersing raw material,making the high-temperature air flow current mixed with raw material ,so that we can achieve the drying goal.it mainly applied to drying process of all kinds of ash raw material.it can be widely used in the fuel..

The drier is consisted hot-wind stove(ready by customer),screw feeder,buffer,blower,the pipes and cyclone.the work process is that the air flow is formed through the negative pressure of blower,the materials enter into the pipe through the screw feeder,so that the hot wind and materials mix..

The smashing machine series are the basic productions of the manufactory.They would be the best choice for smashing PVC,rubber and all kinds of straw,ruderal.The structure of this machine is organized logically,and it is durable and solid,reliable,fixable,easy to operate with.It is also very..

The smashing machine series are the basic productions of the manufactory.They would be the best choice for smashing PVC,rubber and all kinds of straw,ruderal.The structure of this machine is organized logically,and it is durable and solid,reliable,fixable,easy to operate with.It is also very..

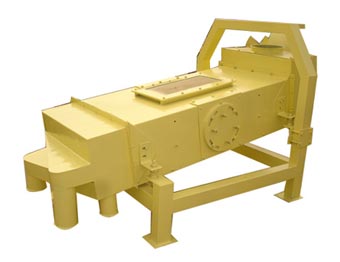

KPJ Series Crusher1.By adopting roll differential theory,this machine is used to extrude and cut big pellet into small one.The roller backup protection has the ability to keep off hard allo[lasm.2.The machine has absorbed all advantages of domestic comminutors,It is a kind of durable..

This machine group can grind all kinds of materials of pellet feed, such as corn, sorghum, grain, legumes, broken cake pellet and others.Building in rotor, grind the raw material with no dead angle, finished products would be more even.Operate door can be moved fully, it is easy to be..

This machine can grind all kinds of materials of pellet feed, such as corn, sorghum, grain, legumes, broken cake pellet and others.This series machine is adopted by pin coupling direct transmission, after the rotor go though with dynamic balancers, it could work on both ways. There is security lock..

The hammer mill of 40 type are special products. It is the most ideal grinding equipment of all kinds of stalk, corn, soybean, rubber, and etc. Structure reasonable, firm durable, safe reliable, easy operation, the vibration small, and the efficiency is high. It is widely used in the..

The hammer mill of 40 type are special products. It is the most ideal grinding equipment of all kinds of stalk, corn, soybean, rubber, and etc. Structure reasonable, firm durable, safe reliable, easy operation, the vibration small, and the efficiency is high. It is widely used in the..

This hammer mill can grind all kinds of materials of pellet feed, such as corn, sorghum, grain, legumes, broken cake pellet and others.Building in rotor, grind the raw material with no dead angle, finished products would be more even.Operate door can be moved fully, it is easy to be..

This hammer mill can grind all kinds of materials of pellet feed, such as corn, sorghum, grain, legumes, broken cake pellet and others.Building in rotor, grind the raw material with no dead angle, finished products would be more even.Operate door can be moved fully, it is easy to be..

The hammer mill of 40 type are special products. It is the most ideal grinding equipment of all kinds of stalk, corn, soybean, rubber, and etc. Structure reasonable, firm durable, safe reliable, easy operation, the vibration small, and the efficiency is high. It is widely used in the..

The series machine is mainly applied to grain crops, low percentage grass plant and some organic fertlizer elements, make the animal feed pellets and organic fertlizer pellets. The diameter of input materials is 2-5mm,the smaller the better.The moisture of raw materials is about 13%,the moisture of..

The series machine is mainly applied to grain crops, low percentage grass plant and some organic fertlizer elements, make the animal feed pellets and organic fertlizer pellets. The diameter of input materials is 2-5mm,the smaller the better.The moisture of raw materials is about 13%,the moisture of..

HKJ 250 ring-die feed pellet mill have got CE certificate, the capacity is 0.5-1.5 ton/h.power: 22kwRing-die pellet mill is on the basis of absorbing advanced technologies domestically and abroad, the pellet mill group has adopted mosaic rotating roller. During working process, the press roller can..

Materials keep dry when gonging into and coming out of the pellet mill, and there is no need to dry it (moisture of raw material>13%). It is used with motor or diesel engine. The output volume is high, energy consumption is low and the operation is convenient.It can produce the sphere pure..

Materials keep dry when gonging into and coming out of the pellet mill, and there is no need to dry it (moisture of raw material>13%). It is used with motor or diesel engine. The output volume is high, energy consumption is low and the operation is convenient.It can produce the sphere pure..

Materials keep dry when gonging into and coming out of the pellet mill, and there is no need to dry it (moisture of raw material>13%). It is used with motor or diesel engine. The output volume is high, energy consumption is low and the operation is convenient.It can produce the sphere pure..

Materials keep dry when gonging into and coming out of the pellet mill, and there is no need to dry it (moisture of raw material>13%). It is used with motor or diesel engine. The output volume is high, energy consumption is low and the operation is convenient.It can produce the sphere pure..

Ring-die pellet mill is on the basis of absorbing advanced technologies domestically and abroad.The pellet mill group has adopted mosaic rotating roller. During working process, the press roller can be adjusted at will. And all functions have reached advanced world standard.The ring die pellet mill..

Ring-die pellet mill is on the basis of absorbing advanced technologies domestically and abroad.The pellet mill group has adopted mosaic rotating roller. During working process, the press roller can be adjusted at will. And all functions have reached advanced world standard.The ring die pellet mill..

1. This type in the digestion absorbs the domestic and foreign vanguard technology success model in the foundation, uses the mosaic revolving roller plate, in the work the drag roll adjusts willfully, each function has achieved the international advanced level.2. Uses force type feeding, and has..

The

series machine is mainly applied to grain crops, low percentage grass

plant, make the animal feed pellets. The diameter of input materials is 2-5mm,the smaller the better.The moisture of raw materials is about 13%,the moisture of finsihed pellets is about 10%.

Under

the advanced..

HKJ250 ring die pellet mill1. This type in the digestion absorbs the domestic and foreign vanguard technology success model in the foundation, uses the mosaic revolving roller plate, in the work the drag roll adjusts willfully, each function has achieved the international advanced level.2. Uses..

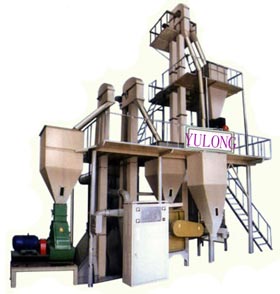

This animal feed line includes the crusher, mixer, pellet mill, cooler and other supporting machine. It can make the pellets from the many kind of crops, it is usually used for big feed factory.This machine group integrates grinding, mixing, adjusting, palletizing, cooling and drying, and..

This feed pellet line is consisted of hammer mill, mixer, pellet mill, cooler and packing machine, meanwhile includes the elevator, magnetic separating and other supporting machines. It has the high capacity, applied to the big plant .This machine group integrates mixing, magnetic separating,..

Ring-die feed

pellet machine is on the basis of absorbing advanced technologies

domestically and abroad, the pellet mill group has adopted mosaic

rotating roller. During working process, the press roller can be

adjusted at will. And all functions have reached advanced world..