Found 28 Matching Products

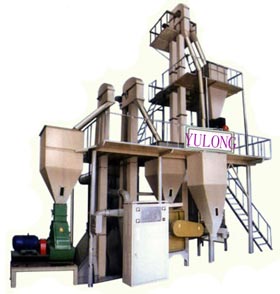

This animal feed line includes the crusher, mixer, pellet mill, cooler and other supporting machine. It can make the pellets from the many kind of crops, it is usually used for big feed factory.This machine group integrates grinding, mixing, adjusting, palletizing, cooling and drying, and..

Grinding,conveying,mixing,pelleting,cooling

and crumbling are integrated.the machine set features reasonable

process,compact structure and small area occupation.low investment and

quick returns.it can produce pellet and powder.itís suitable for livestock,poultry and aquatic product farms to..

T series feed processing plant is a simplify and fully functioning

technology model, is hailed as feed factory with low cost and the cost

of investment is about one third of standard feed factory. The equipment

manual weighing and dosing. Its modality of dosing and comminution (or..

Lark successfully designed and commissioned its first fully automatic controlled plant at M/s Unnat Feeds, Panipat, Haryana, India in February 2008. The plant capacity is 6 ton/hr on pellet and 8-10 MT/ hr on mash. The Plant reflects our designing capability in terms of unique features..

1. Grinding,conveying,mixing,are integrated.2. The machine set features resonable process,compact structure and small area occupation.low investment and quick returns.3. It can produce powder feed.itís suitable for livelock,poultry and aquatic product farms to produce feed.4. We can design..

1. This pellet plant is combined with grinding, mixing, pelleting,

cooling, grading, conveying and electrical controlling system.

2. It can be used for producing high quality livestock and poultry

feed as well as special aqua feed with the capacity of 1-6 metric t/h.

3. With several..

Applicable

to large and medium-sized cultivation companies and small-scale

aquaculture feed processing plants, less power consumed, save power, mixed

uniformly.the machine use the twisted dragon to upgrade the materials,

smash fast,

horizontal mixer mixed more evenly,could work..

With advanced design, the merits of compact and good appearance, the equipment can produce all kinds of high-quality feeding stuff.Reasonable equipment, low cost, low investment, quick working effectsCentralized control, real-time printing, automatic control and measurement, automatic protection,..