Browse Products by Category

Found 262 matching products

Applicable

to large and medium-sized cultivation companies and small-scale

aquaculture feed processing plants, less power consumed, save power, mixed

uniformly.the machine use the twisted dragon to upgrade the materials,

smash fast,

horizontal mixer mixed more evenly,could work..

Even if a hammer mill is properly designed and well matched to its required job, it may not perform well if it is not fed properly.A typical hammer mill feeder is expected to meet following requirements. The feeder must provide a "UNIFORM CURTAIN" of materials to hammer mill grinding..

DL-Malic Acid

【Product Content (Based on C4H6O5)】99.0~100.5%

【Fumaric Acid Content】≤1.00%

【Maleic Acid Content】≤0.05%

【Heavy Metal (Based on Pb) Content】≤10ppm

【Arsenic (As) Content】≤2ppm

【Ignition Residue】≤0.10%

【Water Insoluble Matters】..

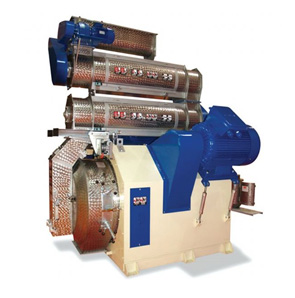

Ring-die pellet mill is on the basis of absorbing advanced technologies domestically and abroad.The pellet mill group has adopted mosaic rotating roller. During working process, the press roller can be adjusted at will. And all functions have reached advanced world standard.The ring die pellet mill..

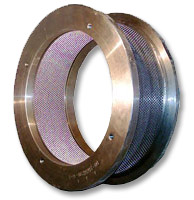

We manufacture a range of pellet dies and are able to meet OEM orders for custom dies.

1. This pellet plant is combined with grinding, mixing, pelleting,

cooling, grading, conveying and electrical controlling system.

2. It can be used for producing high quality livestock and poultry

feed as well as special aqua feed with the capacity of 1-6 metric t/h.

3. With several..

1. This extruder is used for extrusion of full fat soybean, corn,

piglet, soybean meal, cotton seed meal, rice bran etc. It will modify

quality of raw materials and increase digestibility.

2. The Feeder is controlled by FC inverter and ensures raw materials feed into extrusion chamber..

This machine is used for reducing the particle size of different

ingredients in feed . It consists of a rotor on which swinging hammers

are mounted in different patterns which when rotate at high speed,

strike with incoming feed ingredients and break these. Required fineness

of final..

Specifications� Steel housing welded construction� The rotor mounted on the main shaft runs on two long life bearings� V- belt drive transmission� Stainless steel pellet cell� Manually adjusted double roll system� Stainless Steel (*46Cr13) or special alloyed steel cast iron disc� Bolted disc..

Materials keep dry when gonging into and coming out of the pellet mill, and there is no need to dry it (moisture of raw material>13%). It is used with motor or diesel engine. The output volume is high, energy consumption is low and the operation is convenient.It can produce the sphere pure..